Company News

Chain Conveyor--Automation and Intelligence of Material Conveyance

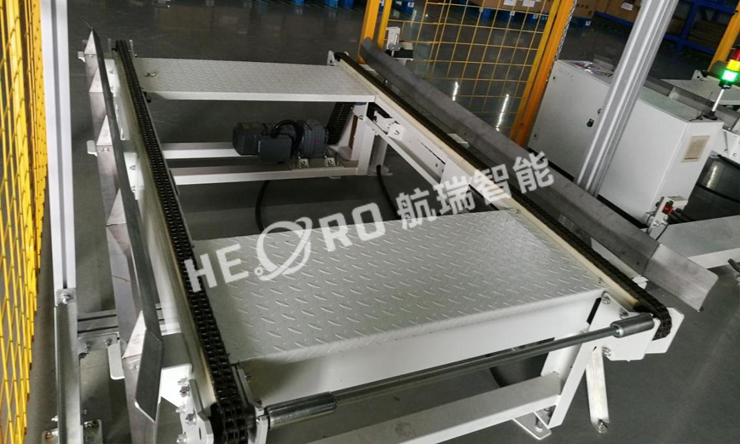

Chain conveyor is a kind of intelligent conveying equipment integrated with advanced technology, the core of which lies in the use of chain as the traction and bearing medium to convey all kinds of materials efficiently and stably, realizing the automation and intelligence of material conveying. Chain conveyor is especially suitable for the storage unit such as pallets, large crates and other items conveying scenarios, showing strong application flexibility and adaptability, has been widely used in various types of industrial production lines.

In product design, the chain conveyor takes into full consideration of different industries, different material characteristics and the diversity of load-bearing needs. According to the difference of load-bearing capacity, the specific form of goods and the specific requirements of conveying, chain conveyor is carefully divided into several categories, of which the most common are two-lane chain, three-lane chain and four-lane chain conveyor. Each chain structure has been strictly designed and tested to ensure that it can play a good conveying effect in the actual application and meet the individual needs of customers.

Two-lane chain conveyor adopts double-chain structure, which ensures the stability and safety of materials in the conveying process, and at the same time, the lower energy consumption and maintenance cost also make it a cost-effective choice.

Four-lane chain conveyor is the best among chain conveyors. It adopts a four-chain structure, which ensures the stability and safety of materials in the conveying process. At the same time, the four-lane chain conveyor is also equipped with an intelligent control system and monitoring device, which can provide real-time feedback on the conveying status, and discover and deal with potential problems in time. This makes the four-lane chain conveyor play a pivotal role in heavy industry, large-scale logistics and warehousing.