Transportation and handling equipment

The lift is an automated logistics equipment that uses the up and down movement of the elevator car to achieve cargo layer changing. The lifting machine has a large transportation volume, high lifting height, and stable and reliable operation, suitable for transporting goods between floors and different heights.

Product classification

According to the different lifting methods, it can be divided into two categories: continuous lifts and reciprocating lifts.

① Continuous lifts are suitable for one-way handling and transportation of single entrances and exits with high flow rates, and are suitable for the transportation of goods between middle and low floors;

② The arrangement of reciprocating lifts is flexible, and materials can enter and exit the lifts from various directions, suitable for multi-directional transportation of multiple layers and entrances.

-

Continuous lift

-

The arrangement of reciprocating lift

Product Features

Features

Picking conveyor is a specialized conveying equipment designed for sorting and conveying products, widely used in logistics, express delivery, e-commerce and other industries.

1. Main components

The picking conveyor mainly consists of automatic control and computer management systems, automatic identification devices, classification mechanisms, main conveying devices, pre-treatment equipment, and sorting gates.

2. Working principle

The working principle of a picking conveyor is to identify and classify items with different characteristics through sensors and computer management systems, and then send them separately to the corresponding processing stages.

3. Product features

The picking conveyor has the characteristics of fast sorting speed, high work efficiency, smooth sorting, and smooth operation.

Product Features

Features

The dismantling/palletizing machine has the function of collecting, temporarily storing, and dismantling empty pallets/bins. Mainly used in conveying systems, it is used in combination with various conveyors to recover empty tools on the conveyor line or distribute empty tools to the conveyor line. Suitable for reducing the occupation of empty space in smart warehouses and reducing the flow rate of transportation.

Product classification

It can be divided into dismantling machine, palletizing machine, dismantling/palletizing machine, Parent and sub-pallet splitting machine, and parent and sub-pallet combination machine

-

Dismantling machine

-

Palletizing machine

-

Dismantling/palletizing machine

Product Features

Features

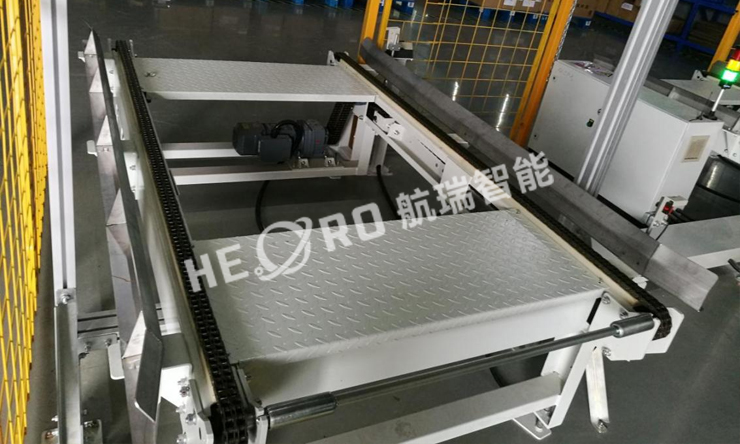

The lift and transfer conveyor is an automated conveying equipment that integrates up and down lifting and horizontal conveying, used to change the direction of material transportation. It can achieve material lifting, loading, reversing, and line changing transportation.

Product classification

Chain type, roller track type, belt type, roller wheel type

-

Roller track type

-

Belt type

Product Features

Features

The telescopic belt conveyor is a logistics conveying equipment that adds an telescopic mechanism on the basis of a regular belt conveyor, and can freely adjust the telescopic length and elevation angle according to the size of the site and actual needs. It is suitable for vehicle cargo loading and unloading or material transmission scenarios with telescopic requirements.

Product classification

Two section, three section, four section, five section

Product Features

Features

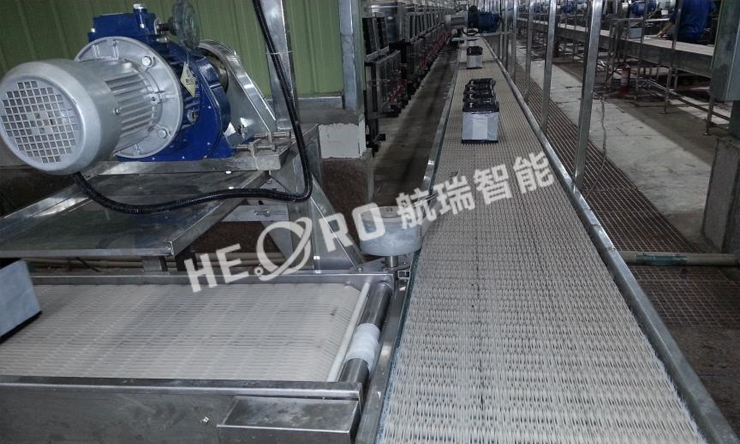

Belt conveyor is a logistics conveying equipment that operates based on the principle of friction transmission, and it transports materials in a continuous and stable manner. Belt conveyors are suitable for conveying cardboard boxes, material boxes, or bulk materials of different sizes and shapes.

Product classification

Ordinary horizontal belt type, climbing type, turning type, chain plate type

-

Ordinary horizontal belt type

-

Climbing type

-

Chain plate type

Product Features

Features

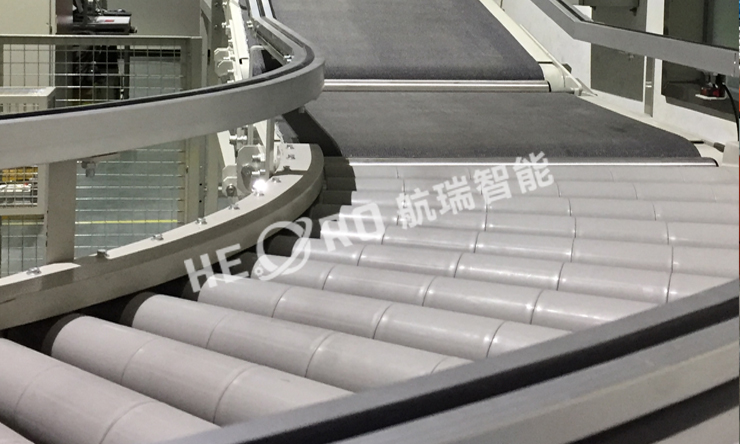

A turning conveyor is a material conveying equipment that can achieve turning transmission on a flat surface. Through specific design and structure, it enables the conveyor to achieve smooth turning movements without interrupting material transportation. Mainly used to solve the layout problem of conveyor lines when changing direction is needed.

Product classification

Belt type, roller type, chain plate type, roller wheel type turning conveyor

-

Roller type

Product Features

Features

Roller conveyor is an important component of logistics transportation, which is an intelligent conveying equipment composed of a series of rollers supported in a frame. Suitable for the transportation of various types of luggage, pallets and other items.

Product classification

① According to the layout form: there are linear, turning, sloping, branching, multi-layer, spiral, telescopic, etc

② Classified by weight: light (such as boxes, bags, etc.), heavy (such as pallets, etc.)

-

Linear

-

Turning

-

Light

-

Heavy

Product Features

Features

Chain conveyor is an intelligent conveying equipment that uses chains as traction and load-bearing to transport materials. Mainly used for material transportation with pallets, large turnover boxes, and other storage units.

Product classification

According to the load-bearing capacity and the shape of the goods, use two chain, three chain, four chain, etc

-

Two chain

-

Three chain